1000 Solutions - July 8, 2019

Sopraloop, a new recycling process for plastic

Written by Tristan Lebleu 3 min read

This solution turns non-recycled plastic into insulation material.

To successfully transition to a sustainable economy, we must move from linear to circular processes. The concept of circularity is quite simple: “It entails gradually decoupling economic activity from the consumption of finite resources, and designing waste out of the system”, as described by the Ellen MacArthur Foundation. But turning this concept into real processes is a real challenge.

In only a few decades, plastic waste has become one of the world’s most visible environmental issues. Indeed, while the quantity of plastic produced keeps increasing every year - from 1.5 million tonnes in 1950 to 322 million tonnes in 2015 worldwide - the recycling processes are still complex and expensive. In the EU, less than 30% of plastic waste is recycled. The rest is sent to non-EU countries for treatment, goes to landfills, is incinerated, or ends up uncollected in nature.

Some plastics are specifically more difficult to recycle, such as opaque and multilayer PET (Polyethylene terephthalate) bottles, full sleeved PET bottles or multilayer PET trays. In the European market, the volume of this non-recycled complex PET waste is estimated around 200’000 tons, which end up incinerated or even landfilled in Europe. Since China’s recent ban on plastic waste imports, it is increasingly urgent to find other solutions.

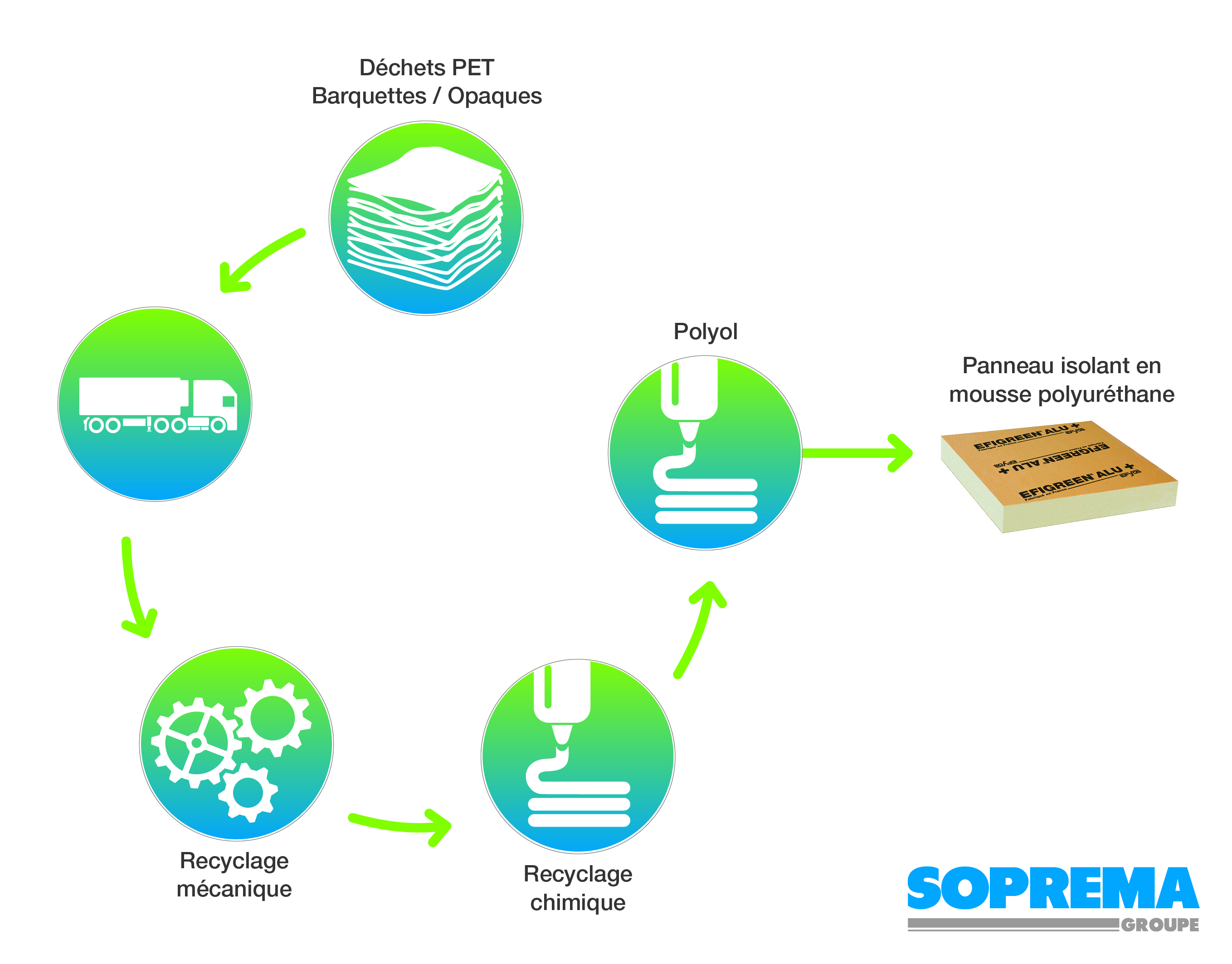

Sopraloop is a new recycling process invented by French company Soprema (partner of the Solar Impulse Foundation), which can turn non-recycled PET plastic waste into house insulation. The process combines, as a world first, both mechanical and chemical recycling. The mechanical recycling is composed of a sorting machine, shredder, washer, and dryer to prepare the waste stream by separating PET components from other contaminants (moisture, paper, other plastics, ..) and shredding the plastic into small pieces. Then, the chemical recycling transforms the PET into polyester polyols.

These polyols, made from recycled PET, will be used in Soprema’s production of polyurethane foams for the insulation market. Soprema aims to substitute 50% of its non-recycled polyols by recycled polyols into the production of polyurethane foams for the insulation market. Sopraloop will enable Soprema to recycle annually 7’000 tons of non-recycled complex PET, which will produce 10’000 tons of recycled polyols. The environmental impact of this new recycling impact is impressive, as it should save - saving 15 000 tons of CO2 equivalent annually, 4’200 tons of crude oil annually and 77 000 mWh of energy annually.

After a thorough review of Sopraloop’s economic and environmental impact by independent experts from our community, the innovative plastic recycling process has been granted the Solar Impulse Efficient Solution Label and is now part of the #1000solutions portfolio.

Written by Tristan Lebleu on July 8, 2019