News - December 21, 2022

Simplifying Access to Geo-Energy - December Solutions Update

Written by Sophie de Blonay 4 min read

A joint venture to reduce buildings' energy consumption, deliveries in Geneva with an hydrogen-powered truck for 2023, a new biomethane production unit in Nouvelle-Aquitaine, intermediary results of an implementation case in Region Grand Est, the scaling of solar fuels and sustainable composite materials technology & More. Discover the latest news about the Solar Impulse Clean and Profitable Labeled Solutions.

Celsius Energy and Vinci Construction Join Forces on Energy Renovation

Celsius Energy, a specialist in surface geothermal (or geo-energy) solutions for heating and cooling buildings, and Vinci Construction have teamed up to offer an energy renovation package combining geo-energy and thermal insulation. According to the two companies, it can reduce a building's energy consumption by up to 93% and its greenhouse gas emissions by 90%. Celsius Energy offers heating and cooling solutions based on renewable underground energy that is compatible with most buildings. This Celsius Energy and Vinci Construction joint offer includes support from conception to commissioning. Celsius Energy's Labeled Solution combines a heat exchanger on inclined probes with a small footprint, a geothermal heat pump and a digital control system to monitor and optimize energy performance. A turnkey solution designed to simplify access to geoenergy.

SUEZ and Waga Energy Inaugurate a Fifth Biomethane Production Unit

In early November, SUEZ and Waga Energy started up a new biomethane production unit in Milhac-d'Auberoche (Dordogne). This is the fifth unit jointly commissioned by SUEZ and Waga Energy. The recovery of biogas from the fermentation of waste in landfill facilities into biomethane is a growing challenge in waste management and in the ecological transition of territories. The SUEZ landfill in Madaillan, located in Milhac d'Auberoche, treats about 105,000 tons of household waste per year and has been recovering the biogas produced by the degradation of waste in the form of heat and electricity. To go further in the production of renewable energy, SUEZ has joined forces with Waga Energy to set up a biomethane production unit. At the Madaillan site, SUEZ will produce up to 20 GWh/year of biomethane thanks to the WAGABOX®, i.e. the annual consumption of more than 3,000 households in the Greater Périgueux area, avoiding the emission of 3,500 tons of CO2e per year into the atmosphere, by replacing fossil natural gas.

GreenGT and its 40-ton Hydrogen Truck on Geneva's Roads

The first Swiss-designed 40-ton electric and hydrogen-powered truck will begin deliveries in January 2023 in Geneva. Tests have already been taking place on Geneva's roads for several weeks. The truck has already covered 1600 kilometers. But on Monday, the 40-ton truck made its first official turn of the wheel in front of the press and the partners of this project called GoH! (Generation of Hydrogen). This hydrogen truck has the same load capacity as a conventional vehicle. It will be used by Migros Geneva, one of the project partners, to bring goods from the distribution center to the various branches in the canton. The project is the result of a collaboration between the Nomads Foundation and four companies: Migros, the propulsion system designer GreenGT, the Services industriels de Genève (SIG) and the group specialized in trucks LARAG. Green GT’s Labeled high-power propulsions can help original equipment manufacturers to deliver market-ready, hydrogen-powered, heavy-duty vehicles, without investing massive time and money in R&D.

Intermediary Results for Grand-Est Region's Experiment with Logikko's Hydrogen Injection System

The Grand-Est region has launched an experiment with Logikko's Hydrogen Injection System solution on its fleet of vehicles. Since April 2022, four vehicles used by the mobile professional work teams (EMOP) are equipped with hydrogen boxes. The experimentation period is 7 to 8 months and the final results are expected in November 2022. This is a first decisive step to deploy hydrogen in the Grand Est Region and reduce the carbon footprint. The expected average results are a 15% reduction in consumption and a 30 to 40% reduction in toxic emissions, depending on vehicle use. Results of a vehicle, at the half of the test period, the tests will end in 2023 for the vehicles having made enough kilometers: Reduction of the consumption of the vehicle: -10%, Reduction of the opacity (pollution): -50%, Nox reduction: -27%, Reduction of HC (unburned) : -100%. Out of the 4 vehicles, only one ran enough, the 3 others ran too little (problem with these vehicles: they only run during school time over short distances). Logikko has also received a letter of intent from the DGAC, which is part of the Ministry of Transport, attesting to their gain on the vehicles and their intention to continue alongside Logikko, especially concerning the generators.

Synhelion Raises CHF 22 Million Investment to Drive the Scaling of Solar Fuel Production

Synhelion has raised CHF 22 million investment to drive the scaling of solar fuel production. The finds were primarily provided by existing investors and selected new strategic investors, including Swiss International Air Lines (SWISS). The proceeds of the investment round will accelerate the company’s growth and support the scaling and commercialization of Synhelion’s sustainable fuel. By successfully producing syngas on an industrial scale using solar heat, Synhelion reached its last decisive technical milestone for the industrial production of sustainable solar fuels in August 2022. Shortly after, Synhelion started construction of DAWN – the world’s first industrial plant to produce sustainable fuels using solar heat. Among Synhelion’s existing and new investors are world leading companies with outstanding track records and technological excellence, such as the SMS group, CEMEX, Eni, AMAG Group, and SWISS. The portfolio of investors creates significant synergies that enable Synhelion to accelerate the industrialization and global roll-out of the solar fuel technology.

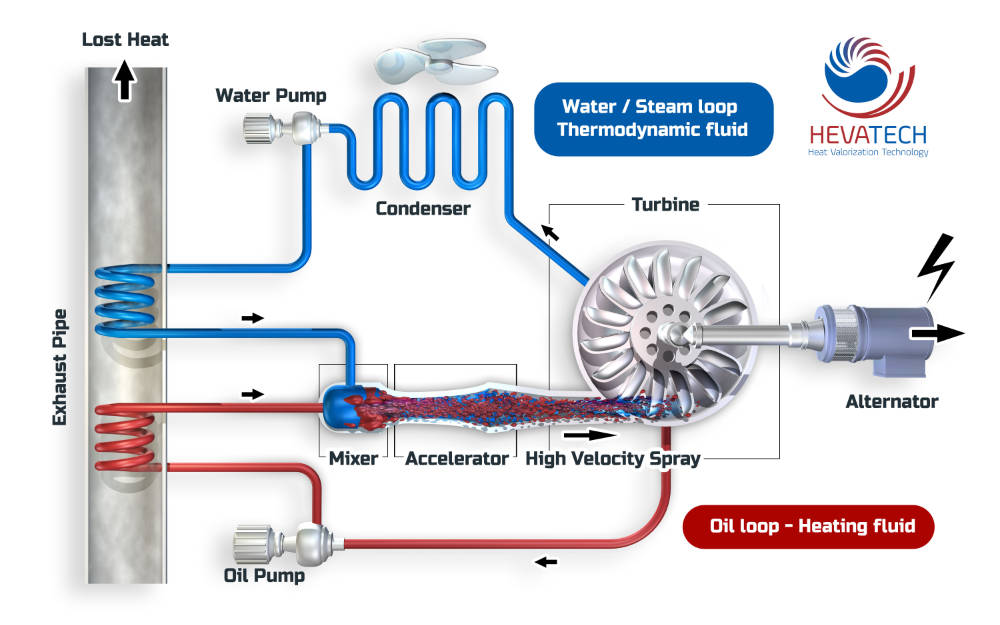

Hevatech Raises EUR 4 Million

Hevatech raises EUR 4 million to market its waste heat recovery and industrial decarbonization system, Turbosol, on the European market. This fundraising is carried out with the Banque des Territoires on behalf of the State within the framework of France 2030, and EREN Groupe, accompanied by two historical investors of the company. The funds will allow Hevatech to accelerate its development and the commercial deployment of its innovative and economical solution. Hevatech is positioned in the industrial energy efficiency market industry, and more specifically on the recovery of waste heat into electricity via its innovative and Labeled Solution, Turbosol. Hevatech provides a short-term response to the economic challenges of optimizing energy costs and to the ecological challenges of decarbonizing the industry, which generates between 10% and 15% of total greenhouse gas emissions. Hevatech offers a turnkey solution to industrial players who want to reduce their energy bills and CO2 emissions.

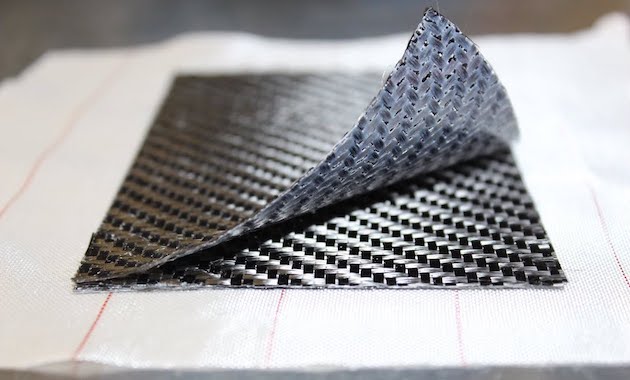

CompPair Gets a FIT Tech Growth Loan to Develop its Sustainable Composite Materials Technology

The Foundation for Technological Innovation (FIT) has decided to support CompPair with a FIT Tech Growth loan of 500’000 CHF to bring its technology to new markets such as aerospace and sports. As a spin-off of the École Polytechnique Fédérale de Lausanne (EPFL), the start-up's mission is to extend the life of products and contribute to the circular economy. With its Labeled Solution Smart Prepeg, CompPair has developed smart and sustainable composite materials that are able to repair themselves and be better recycled. CompPair's vision is to offer total circularity to the composites industry. These materials are used everywhere: in the aerospace, automotive, wind, marine, and sports industries... In total, the global composites market represents 100 billion dollars and has grown by 40% since 2014. Nevertheless, these materials are sensitive to damage and current repair solutions are costly, time-consuming, and the industry produces tons of unrecycled waste. CompPair is addressing this issue by developing a unique self-healing technology for composites to reduce maintenance costs, manufacturing defects and extend their life.

Written by Sophie de Blonay on December 21, 2022