Technical Article - July 29, 2025

The Right Role for Hydrogen in the Energy Transition

Written by Léon Pieyre 6 min read

Strategic Hydrogen: Efficiency Over Ideology

Hydrogen is not a silver bullet - and treating it like one could waste precious time and resources.

While hydrogen has a critical role to play in decarbonizing sectors like steel, shipping, and aviation, it’s neither efficient nor necessary for every application. Using hydrogen where better alternatives exist, such as direct electrification in cars or buildings, risks slowing down the transition and inflating costs. Like any tool, hydrogen works best when used with precision. The challenge now is to cut through the hype and deploy it where it makes the most sense - technically, economically, and environmentally.

This article aims to shed light on these aspects, contributing to demystifying a topic that too often sparks dogmatic positions rather than pragmatic dialogue.

A Rising Demand for Hydrogen

As decarbonisation goals accelerate, investment interest in hydrogen applications is rising sharply - though many projects are still at early stages and success will depend on targeted, scalable use cases. In 2024, global investment in green hydrogen was estimated at around $8 billion, with market analysts anticipating substantial growth through 2030. Major investors are committing capital at scale–such as the $2 billion Hy24 infrastructure fund, which supports advanced green hydrogen projects across Europe and Asia.

Our latest article on hydrogen colours briefly touched upon the current sectors of implementation for hydrogen, but what is their distribution and how will the related numbers evolve ?

The Expansion and Diversification of Hydrogen Operations

Nowadays, roughly 95% of the hydrogen demand originates from industrial sectors such as fertiliser manufacturing, desulfurisation and hydrocracking to develop cleaner fuels or using hydrogen as feedstock for plastics2. The remaining 5% are concentrated into the fields or energy production (hydrogen fuel cells, energy storage)3, aerospace and spaceflights (rocket propulsion)4 and emerging uses such as clean transport (trucks, buses) or hydrogen blending in gas grids5.

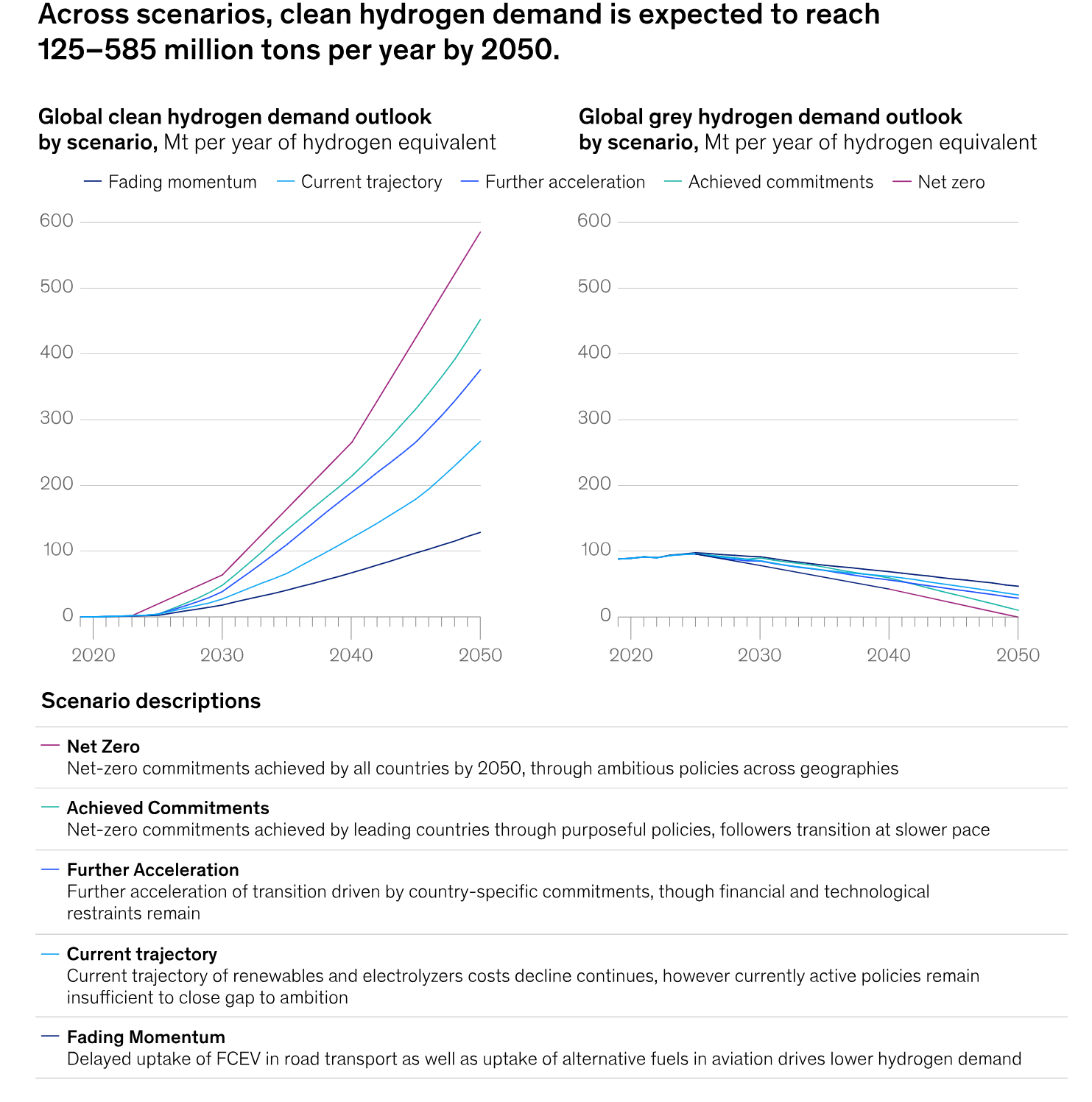

Hydrogen's deployment landscape is projected to diversify significantly. According to McKinsey&Company's 2023 Global Energy Perspective, the future distribution may resemble the following:

- 50-60% for Industrial Applications: further production of ammonia, methanol and steel, growth in low-carbon processes.

15-20% for Transport: fuel cell vehicles development (especially shipping and heavy-duty transport).

20-25% for Power Generation & Storage: electricity generation, grid balancing, long-term energy storage.

5-10% Building & Heating: growth of residential and commercial heating applications.

These figures further illustrate the attractiveness of hydrogen for various industries. However, identifying where and why hydrogen offers the most value – and where it does not – is crucial.

Liquid Hydrogen already fueled NASA's Apollo program, the missions that sent humans to the moon more than half a century ago !

Liquid Hydrogen already fueled NASA's Apollo program, the missions that sent humans to the moon more than half a century ago !

Sectors Primed for Hydrogen Rollout

Heavy Industry

Producing steel, iron, chemicals or cement is essential to our modern way of life. However, the heavy industry is responsible for nearly 40% of global CO2 emissions6. This is primarily due to the high heat (1,400-1,700°C)7 required to convert materials to steel or cement – or the coal, oil and natural gases used as feedstock for the production of chemicals.

Hydrogen produced from renewable energies could be a key-player in decarbonising the heavy industry by serving as an efficient and clean reducing agent in the production of iron. The process would emit water vapor instead of CO2. As an example, the HYBRIT initiative stores 100m3 of green hydrogen gas to produce fossil-free iron and steel on an industrial scale, aiming to reduce Sweden and Finland’s carbon dioxide emissions by 10% and 7% respectively. This could potentially reduce operation costs of hydrogen production by up to 40% !

During the Haber-Bosch process, hydrogen reacts with nitrogen to form ammonia (NH3); a critical component for fertilisers. Currently, grey hydrogen derived from natural gas or coal is the main type of hydrogen used in this process. Switching to a cleaner form of hydrogen in the production process of ammonia could significantly reduce its CO2 emissions. Using blue hydrogen could cut these emissions by up to 80%, green hydrogen up to 90% !I

The First Ammonia project in Texas, USA, is scaling a 100 MW electrolyser to boost green hydrogen production and deliver around 300 tonnes of green ammonia per day.

Hybrit Hydrogen Storage Facility

Hybrit Hydrogen Storage Facility

Heavy-duty Transport

By enabling faster refuelling, optimised payload, and higher range, hydrogen might help to solve various challenges encountered by long-haul transports. Heavy-duty vehicles are progressively shifting towards battery electric vehicles (BEVs).

Even so, electrification alone won’t allow a full decarbonisation of heavy-duty transport. For example, long-haul trucks that require 1-2MWh batteries often take several hours to fully charge, increasing trip durations by up to 35%. Using hydrogen fuel cells or combustion engines could reduce the charging time to 10-15 minutes instead.

The Solar Impulse Foundation has labelled Ways2H’s Hydrogen Solution, which was adopted by the UK to serve as many as 1,600 fuel cell buses by providing 500kg to 1 ton of renewable hydrogen fuel per day. Heavy-duty trucks, lorries, or other heavy goods vehicles, they could seriously optimise their travel range and cover up to 11,000 road kilometres per day! If fuel sources of long-range trucks shifted from conventional fossil fuels to renewable green hydrogen, greenhouse gas emissions could be reduced by approximately 89%.

In the world of cargo-shipping, Maersk is heavily developing production of green methanol as a fuel for its ships. They are collaborating with Carbon Sink LLC to produce 100,000 tonnes of green methanol, a combination of green hydrogen and biogenic CO2, per year. Currently, 13 dual-fuel Maersk cargo-ships running on green methanol are active. By the end of the year, 19 ships will be deployed and generate annual CO2 emissions savings of around 2.3 million tonnes. On top of that, the changes required to incorporate this technology enabled ships to increase their capacity from 15,000 to 15,690 TEU( Twenty-foot Equivalent Unit).

The green methanol developed from green hydrogen could be an inspiration for the development of cargo-transport

The green methanol developed from green hydrogen could be an inspiration for the development of cargo-transportLong-Term Storage

Hydrogen can also be used to store surplus energy from wind and solar power and reused when needed, instead of wasted. Power-to-gas (hydrogen) could provide weeks to months of storage, unlike batteries, which are limited to hours or days.

In Utah, USA, the world’s largest hydrogen storage site is under construction; the Advanced Clean Energy Storage(ACES) project. It will provide over 300 GWH of energy storage in enormous salt caves, each roughly spacious enough to house the Empire State Building. Launched by Mitsubishi Power and Magnum Development, the initiative will use these salt caverns to store renewable energy. Mike Ducker, Vice President of Renewable Fuels at Mitsubishi Power stated that:

“You’d need roughly 40 GW worth of lithium-ion batteries to have the same amount of storage potential in just one of our caverns.”

By 2026, there will be 4 caverns available for storage. The caverns are created by dissolving salt with water (solution mining) and produce brine. This product will remain contained within evaporation ponds that feature groundwater monitoring and leak detection systems ensuring a minimal environmental impact. Moreover, salt formations have low porosity and the ability to naturally close fractures, ensuring long-term gas containment.

Sectors Incompatible with Hydrogen Development

There are various industries where hydrogen does not seem to be the most promising alternative. In various situations, electrification, batteries or other low-carbon solutions have a competitive advantage over hydrogen in terms of efficiency, cost and plausibility.

Structural Heating

Heat pumps are far more efficient than hydrogen heating sources. Hydrogen boilers typically operate at 60-70% efficiency, compared to heat pumps which can reach 300-500% efficiency due to their ability to transfer rather than generate heat8. In addition, repurposing infrastructures in a way that hydrogen can be incorporated into gas pipelines is far too expensive and complex.

Passenger Cars and Light Duty Vehicles

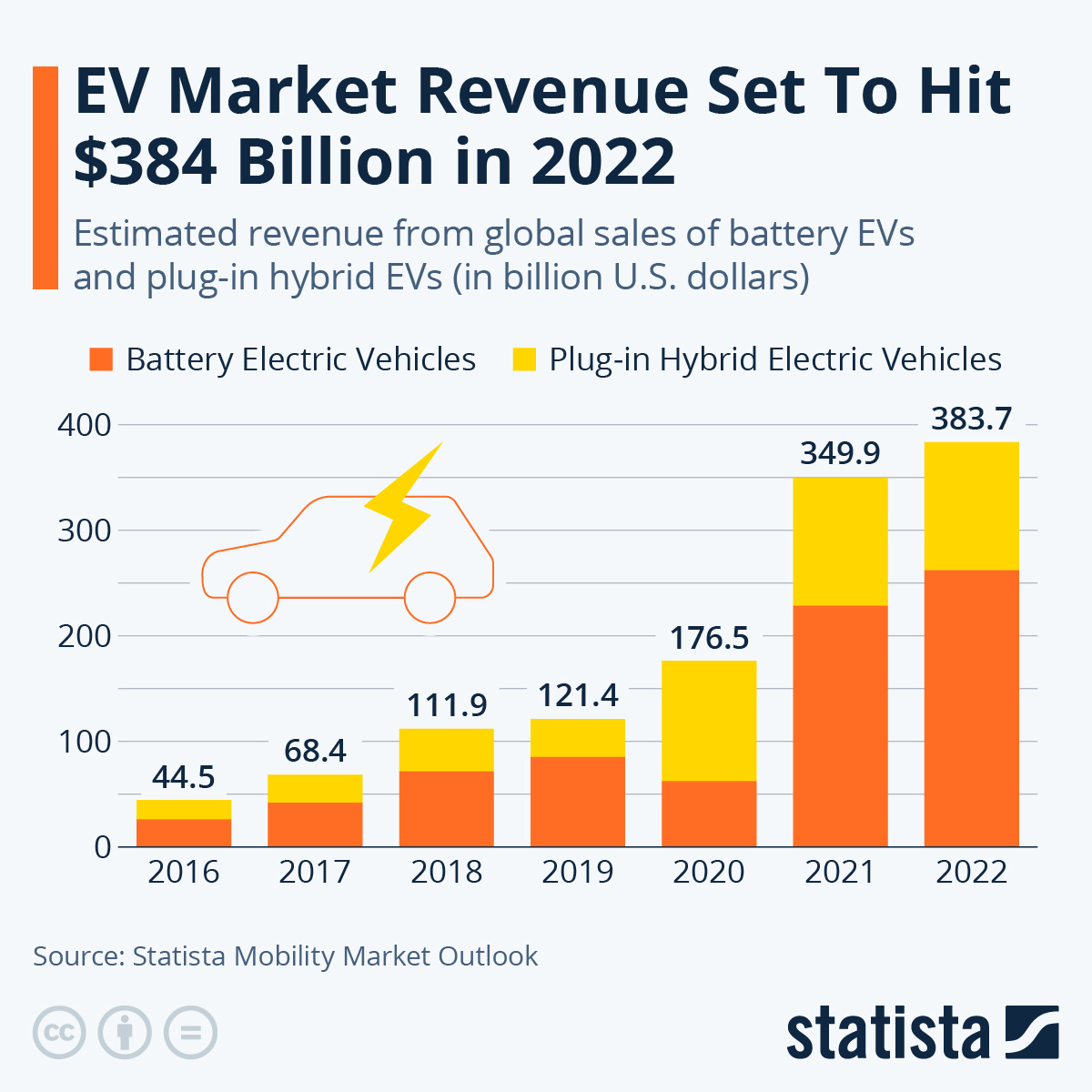

Although we saw the benefits of hydrogen technology for heavy-duty transport, they do not apply when it comes to smaller cars aimed for short transports or even urban public transports. Light duty vehicles require way smaller and lighter batteries than heavy duty transports. A 1,000 km-range electric truck may need 4-6 tons of batteries9, but a passenger car’s battery will only weigh 400-600 kg and have a range of 500-600 km.10 For this range, energy efficiency (75-85% for BEV’s, 30-40% for hydrogen-powered vehicles11) will be an advantage over the quick recharging characteristics of hydrogen vehicles.

Besides, battery-electric vehicles (BEVs) are spread globally and supported widely. There are currently over 26 million BEVs on the market12. In contrast, there are only 70,000 fuel-cells on the same scale13. Developing hydrogen refueling infrastructures to compete with BEVs would be sparse, expensive and wouldn’t offer a significant advantage in terms of environmental footprint.

The same arguments are valid for urban public transports like metro trains and buses, which are short-range, low-power applications that similarly favour energy efficiency.

Graph demonstrating the expansion of BEV's, by Statista Mobility Market Outlook

Graph demonstrating the expansion of BEV's, by Statista Mobility Market Outlook

Low-Temperature Industrial Processes

Processes like food processing, textiles, paper drying or bottle washing require heat from 60-150ºC14. Once again, electric resistive heaters or heat pumps convert energy to heat with great efficiency (100% for resistive heater15, up to 300-500% for heat pumps16) in contrast to hydrogen-based heating (30-40%)17. As heat pumps and resistive systems are so efficient, they consume far less energy and are cheaper as a result.

Fueling the Future, Strategically !

In the UK, three separate trials of hydrogen implementations for residential heating were abandoned mid-2024 due to concrete evidence proving how electric heat pumps were more efficient and cost-effective. One of the projects alone was estimated to cost up to £200 million had it been implemented.

These trials underscore the need to invest in hydrogen where it delivers real value and scalability. Strategic initiatives – like the European Hydrogen Bank, now allocating over €1 billion to green hydrogen projects – demonstrate how targeted funding can accelerate impact. Complementing this, the European Commission has adopted a new emission methodology for low-carbon hydrogen, completing the EU’s regulatory framework and providing legal clarity for investors. Together, these efforts strengthen confidence in the sector and help position hydrogen as a credible solution.

The Solar Impulse Foundation is committed to contributing, with Climate Impulse, to demonstrate the strategic value of hydrogen, not across the board but where it makes sense, providing an inspiring blueprint for sustainable innovation and deployment. In that spirit, our upcoming article will feature insights from a seasoned hydrogen expert, who will share his perspective on the industry's future outlook... Stay tuned !

References:

1. https://energiesmedia.com/why-investing-in-hydrogen-could-be-your-smartest-move-in-2025/

2. https://www.iea.org/energy-system/low-emission-fuels/hydrogen

4. https://www.eia.gov/energyexplained/hydrogen/use-of-hydrogen.php

6. https://www.brookings.edu/articles/the-challenge-of-decarbonizing-heavy-industry/

8. https://h2sciencecoalition.com/blog/hydrogen-for-heating-a-comparison-with-heat-pumps-part-1/

9. https://thundersaidenergy.com/downloads/electric-trucks-what-battery-sizes/

10. https://blog.evbox.com/ev-battery-weight

11. https://insideevs.com/news/406676/battery-electric-hydrogen-fuel-cell-efficiency-comparison/

13. https://en.wikipedia.org/wiki/Alternative_fuel_vehicle

14. https://www.sciencedirect.com/science/article/pii/S0301421522006024

15. https://physics.stackexchange.com/questions/1493/how-efficient-is-an-electric-heater

16. https://www.wbcsd.org/wp-content/uploads/2023/10/Industrial_heat_pumps_time_to_go_electric.pdf

17. https://www.sciencedirect.com/science/article/pii/S0306261923008280

Written by Léon Pieyre on July 29, 2025