News - September 10, 2025

Solution Deep-Dive: FluidSolids

Written by Hugo Kermiche & Léon Pieyre 3 min read

On this visit, representatives from the Solar Impulse Foundation met with the FluidSolids team at their headquarters in Zürich, Switzerland.

FluidSolids transforms biowaste into a sustainable alternative to plastic. The result is a highly resistant, flexible and scalable biocomposite that can be integrated in various industry sectors.

We sat down with Founder Beat Karrer, CEO Lukas Scherrer, and CTO & Chemist Francesca Tancini, who shared insights into their innovative journey, the challenges they've encountered, and their vision for the future of FluidSolids.

Various FluidSolids Actors

Beat Karrer founded FluidSolids after comprehending the amount of waste streams being discarded without purpose. 15 years ago, he began exploring ways to replace petroleum-based plastics with natural alternatives–driven by the opportunity to turn waste into value.

Lukas Scherrer, long concerned about the amount of plastic ending in our waters, initially joined the company’s Board of Directors. Over time, he took on a more hands-on, tactical role within the organisation.

Dr. Francesca Tancini is head of R&D at FluidSolids since she started as the employee Nr. 1 in 2015. Chemist by education, her role focuses on transforming available biowaste into practical, high-performance solutions.

The FluidSolid Biomposites

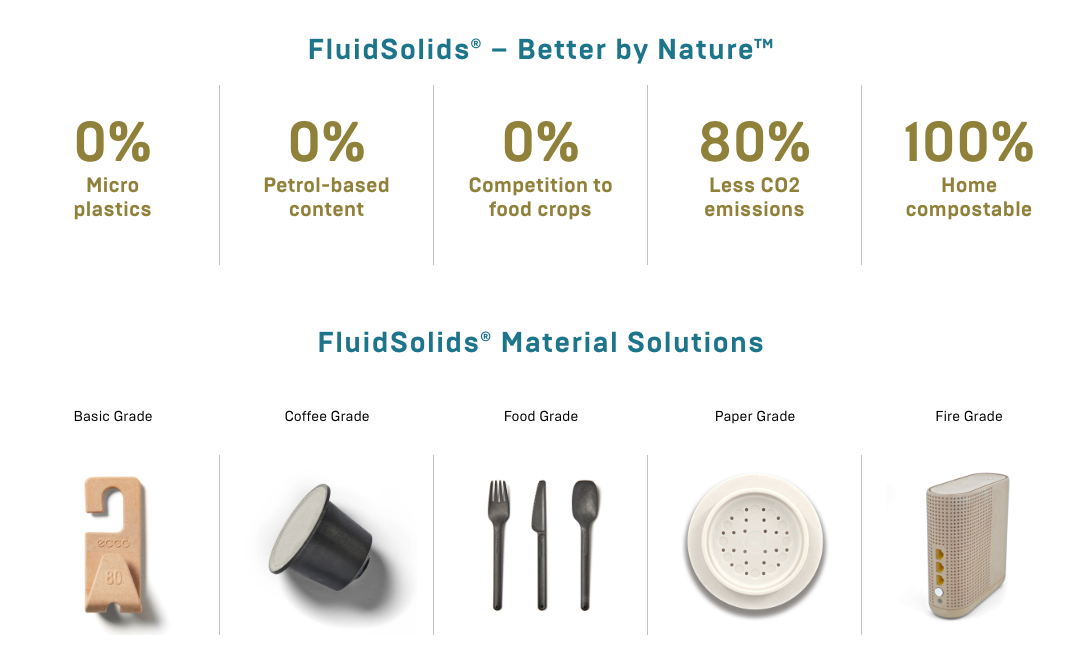

FluidSolid’s material is entirely bio-based and contains no plastic. It is derived from side streams of the agricultural or food industry that have no inherent value in their original form. Using its proprietary technology, FluidSolid converts these elements into a new material compatible with standard industrial processes such as injection molding.

Fluidsolids products

Fluidsolids products

Challenges

F. Tancini and B. Karrer both emphasized that competing with plastic– a standard material so deeply embedded into our daily lives–remains a considerable obstacle. Regulatory standards for quality and safety are all based on plastic properties, yet FluidSolids’ biocomposites are fundamentally different. Moreover, adopting them requires adjustments across the entire supply chain

L.Scherrer highlighted that although exciting, a new material can also appear risky to potential clients. Convincing them to adopt FluidSolids at scale is no small task–especially when their financial structure doesn't always align with carbon reduction goals.

Current situation

Currently, FluidSolids operates as a technology provider: developing materials, demonstrating their functionality, and bringing them to market at pilot scale. B. Karrer emphasizes that, despite not being a high-volume manufacturer, the company has clearly shown its potential to reduce plastic pollution in sectors such as single-use packaging and electronics.

Most recently, they introduced their own compostable coffee capsule as a concrete example of the material’s promises. Besides, FluidSolids already has several patents protecting their material and formula, as outlined by F. Tancini.

Growing momentum

B. Karrer recalls that when he first shared his vision 12 years ago, many doubted the feasibility of selling materials made from waste. Today, however, he sees a shift in momentum: more companies are beginning to upcycle side streams into valuable resources.

Rather than viewing this growing competition as a threat, Karrer welcomes it as a catalyst for sector growth and broader public acceptance. He’s also confident that the emerging bio-economy is large enough to accommodate multiple players.

What next ?

The FluidSolids team aims to elevate the company's global presence and reputation by collaborating with driven, influential partners who can influence consumer habits and shape industry norms. They identify significant growth opportunities for their solution, especially in high-volume, short life-cycle applications–sectors where high-tech materials are frequently overapplied, often without clear necessity.

The driving forces behind FluidSolids are confident in their ability to become a leading technology provider by supporting industries in advancing sustainability, curbing plastic waste, and enhancing economic efficiency.

Advantages of SIF label

L. Scherrer views the label as a trusted third-party endorsement that lends both scientific and business credibility to the solution. Through a strong relationship with the Solar Impulse Foundation–along with shared videos and interviews–FluidSolids has been able to highlight the strength of its network and its connection to a broader ecosystem.

Written by Hugo Kermiche & Léon Pieyre on September 10, 2025