News - June 29, 2021

Latest News from our Labeled Solutions - June

Written by Eliott Carruthers

Country and city-wide implementation, valorization of PPE and global consumer brands swarming to circular plastic recycling technology. An abundance of successes from the Labeled Solutions in the month of June.

L’Oréal, Nestle, Pepsi, Suntory and Food Europe form breakthrough consortium with Carbios

The Consortium has announced that it has successfully produced the world’s first food-grade PET bottle samples made entirely from enzymatically recycled plastic. Each member of the Consortium has successfully produced sample bottles for one of its flagship products, including Biotherm®, Perrier®, Pepsi Max® and Orangina®. PET plastics that otherwise would accumulate in landfill or be incinerated, can now be re-integrated into a circular and continuous recycling system. In September 2021, Carbios will inaugurate its industrial demonstrator before starting an industrial unit by 2025 with a capacity of 40,000 tonnes. Together, these brands will now work on the industrialization of this innovation to help meet the global demand for sustainable packaging materials.

Carbios’ CEO Jean Claude Lumaret : “In a world first, we have created food-grade clear bottles from enzymatically recycled colored and complex plastic with identical properties to virgin PET, and in partnership with the Consortium, we have proved the viability of the technology with the world’s leading brands. This is a truly transformational innovation that could finally fully close the loop on PET plastic supply globally, so that it never becomes waste.”

LightBlue contracted for Mauritius Island food waste prevention program

Business Mauritius, with the financial support of HRDC, has contracted LightBlue Environmental Consulting to design and implement an ambitious food waste prevention program on Mauritius Island. 10 pilots are embarking restaurants on a 6-month journey to cut on food waste, reduce unnecessary costs and negative environmental impacts, and reach the international certification and benchmarking standard The PLEDGE™ on Food Waste. Each pilot will receive technical training to implement an advanced food waste monitoring system in their kitchen, using LightBlue’s FIT Food Waste Monitoring Tech. This agile tech Solution tracks and reduces both food waste and its associated costs in commercial kitchen environments – reducing food waste by between 25-35%.

Bratislava launches large-scale smart waste management with Sensoneo

Labeled Solution Sensoneo is leading a project targeted at waste digitalization and efficient waste collection for the city of Bratislava. The project is supported by a grant from the European Innovation Council, which Sensoneo received in the summer of 2020 for the large-scale deployment of its solution to demonstrate its environmental and economic benefits. The project includes several stages that will be implemented continuously until April 2022. The city expects cleaner public spaces, savings on waste collection-related mileage and emissions as well as the possibility for early intervention in the case of overfilled containers. Considering the scope, size and technologies applied, the project represents the first-of-its-kind deployment on a global level.

Ways2H to bring 40 waste-to-hydrogen refueling stations across the UK

Ways2H waste-to-hydrogen production facilities will supply Element 2 hydrogen refuelling stations to serve as many as 1,600 fuel cell buses per day. The two companies envision as many as 40 sites that will each provide 500 kg to 1 ton per day of renewable hydrogen fuel. As they begin to arrive in the UK, this will be enough for a heavy-duty truck, lorry or other Heavy Goods Vehicle to cover 11,000 road kilometres (6,835 miles). The first project is planned for a location in Scotland, a leading hydrogen nation that has aggressive goals to develop a hydrogen economy.

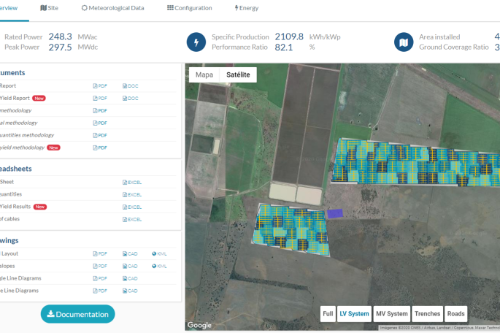

RatedPower CEO Andrea Barber selected as European Laureate for Cartier Women’s Initiative

The initiative empowering women entrepreneurs driving social-environmental change has recognized RatedPower’s Andrea Barber as a leading impact entrepreneur. The Spanish start-up she co-founded and its pvDesign, labeled August 2020, offers software as a service (SaaS) providing the smartest ways to design solar energy plants through the automation of their engineering - aimed at tackling the pre-existing inefficiencies of solar plant design. If only 1 of every 200 projects studied by pvDesign were annually installed, the energy generated would be 10800 GWh, equivalent to the electricity consumption of 3 million households.

Messageries Laitières implements Opalean platform

With the aim of digitizing its processes, Messageries Laitières has chosen to manage its European pallet flows using the Opalean software. The dairy operator can now effectively manage its end-to-end flows from its thirty production sites simplifying its packaging management with chartered carriers. Opalean tracks pallets in real time allowing them to be recycled efficiently and effectively, recovering close to 100% of reusable pallets. The impact of this automated platform: 445,000 tons of CO2 stored per year through 10 million pallets managed, and up to 2000 hectares of forest preserved per year, avoiding 5 to 7.5 million lost pallets annually.

UBQ’s Technology converts PPE and other unrecyclable waste into everyday products

The Israeli start-up is using its technology to actively recycle personal protective equipment (PPE), as well as other unrecyclable waste. The waste feedstock of UBQ includes food scraps, garden trimmings, cardboard, paper, mixed plastics and in recent months, a great amount of PPE in their heterogenous waste stream. Their advanced conversion technology transforms landfill-destined waste into a bio-based material substituting oil-based plastics in the manufacturing of thousands of everyday products. The technology works as a zero waste system and on average reduces 15 tons CO2eq per ton of UBQ material output.

Biden administration report recognizes RecycLiCo™

The White House report “100-Day Battery Supply Chain Review”sees the growing volume of spent lithium-ion batteries as a resource lost to landfills or shipped abroad for recoveries. American Manganese’s patented RecycLiCo technology is cited in the report as a pioneer in advanced battery recycling and leading the way in this domain. The Labeled Solution facilitates a reduction of 2 tons of CO2 per ton of material processed.

Written by Eliott Carruthers on June 29, 2021