Technical Article - June 23, 2025

Decoding the Hydrogen Rainbow

Written by Léon Pieyre 7 min read

Hydrogen Series

Last year, our founder Bertrand Piccard announced the launch of his groundbreaking upcoming mission: Climate Impulse. After going around the Earth with the Solar Impulse airplane between 2015-2016, Bertrand Piccard aims to push the boundaries of clean technologies pioneering even further. In 2028, he will attempt another trip around the world, this time non stop, zero emissions, in a plane powered by green hydrogen.

Green hydrogen is an emerging term in the field of environmental sustainability, and even sits at the center of today’s sustainability debate: hailed as a clean energy hero by some, criticised as a costly distraction by others. Its production methods vary dramatically in carbon impact - from fossil-based “grey” hydrogen to truly green hydrogen made with renewable electricity. Critics question its inefficiency and scalability, especially for land transport and heating. Yet in hard-to-decarbonize sectors like aviation, where energy density matters and battery solutions fall short, hydrogen remains one of the few viable paths toward true zero-emission flight.

This article is the first in a series designed to help you better understand the basics about hydrogen - and its climate impact.

Hydrogen on Earth

To understand why hydrogen is central to our society and increasingly popular as a potential key player in reaching a sustainable future, we must explore its fundamental role:

0.00005% of the Atmosphere’s volume in the form of gas (H2).1

Hydrogen atoms constitute approximately 11% of water’s total mass.2

10% of our body mass.3

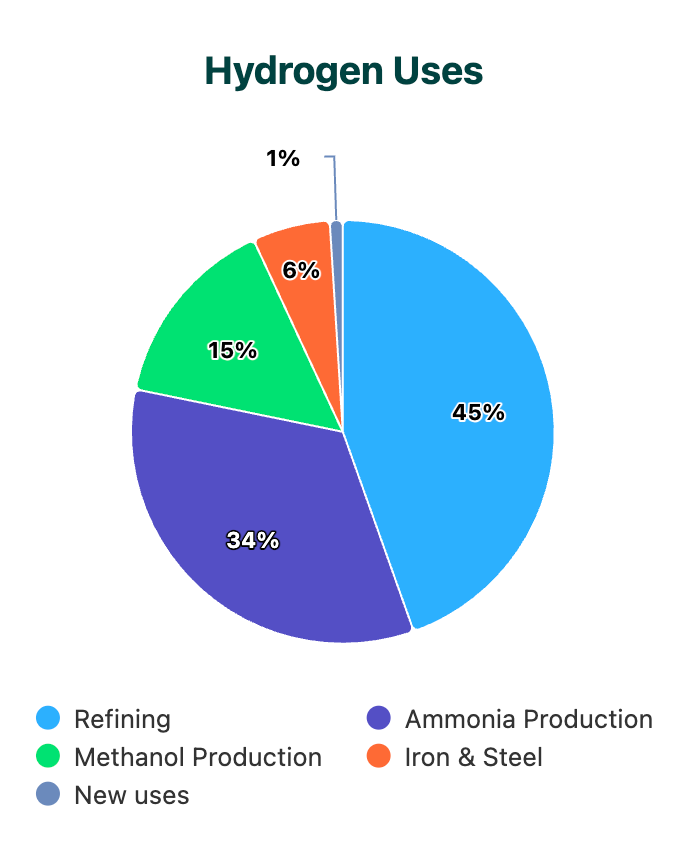

Hydrogen also has an immense impact on our everyday lives: according to an IEA report, 90 million tonnes of hydrogen are produced globally each year only for industrial purposes (ammonia production, oil refining). Additionally, hydrogen is used in the sectors of energy (fuel cells, energy storage), aerospace and spaceflights (propulsion for rockets) or clean transport (public transports, cargo-shipping.) However, not every type of hydrogen can be used as a sustainable source of energy or fuel. There is a clear distinction to be made between the different types and colours of hydrogen according to their production method.

An Insight on the 2023 Global Hydrogen Demand by Stanford University

Carbon-Emitting Hydrogen Colours

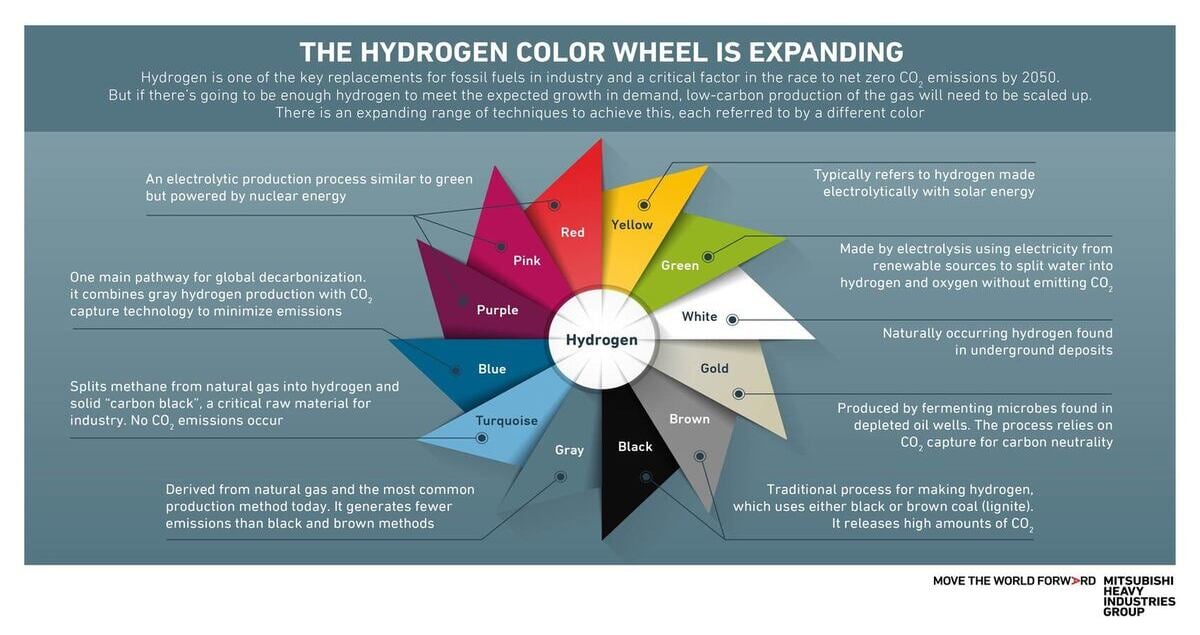

Black or brown hydrogen is produced by coal gasification, a process that generates significant CO2 emissions (19 tCO2/tH2)4. It is used to synthesise ammonia, especially in China and India which are coal-rich countries that use ammonia as a source of fertilizer or in South Africa to convert coal to liquid fuels5.

Grey hydrogen is a product of fossil fuels through steam gas reforming or coal gasification. Grey hydrogen is the world’s primary hydrogen solution today; it represents 95%6 of our society’s hydrogen consumption and is used for hydrogenation processes in food or electronics, or to produce methanol globally. Presently, it is the most attractive hydrogen option financially as it costs around $1-$2 per kilogram of H27. However, it is not a viable option as it releases 10-19 tons of CO2 per ton of H2 into the atmosphere8.

Obtained from natural gas by steam gas reforming paired with carbon capture and sequestration (CCS), blue hydrogen is seen as a “bridge technology” on the path to full decarbonisation. It significantly reduces CO2 emissions (1-4 tCO2/tH2)9 compared to grey hydrogen and remains relatively cheap ($1.5-$3 per kilogram of H2)10. Blue hydrogen is increasingly being implemented into the transport industry as a power source for heavy trucks, buses, trains, and ships.

The Hydrogen Colour Wheel

Promising and Technologically Accessible Hydrogen Colours

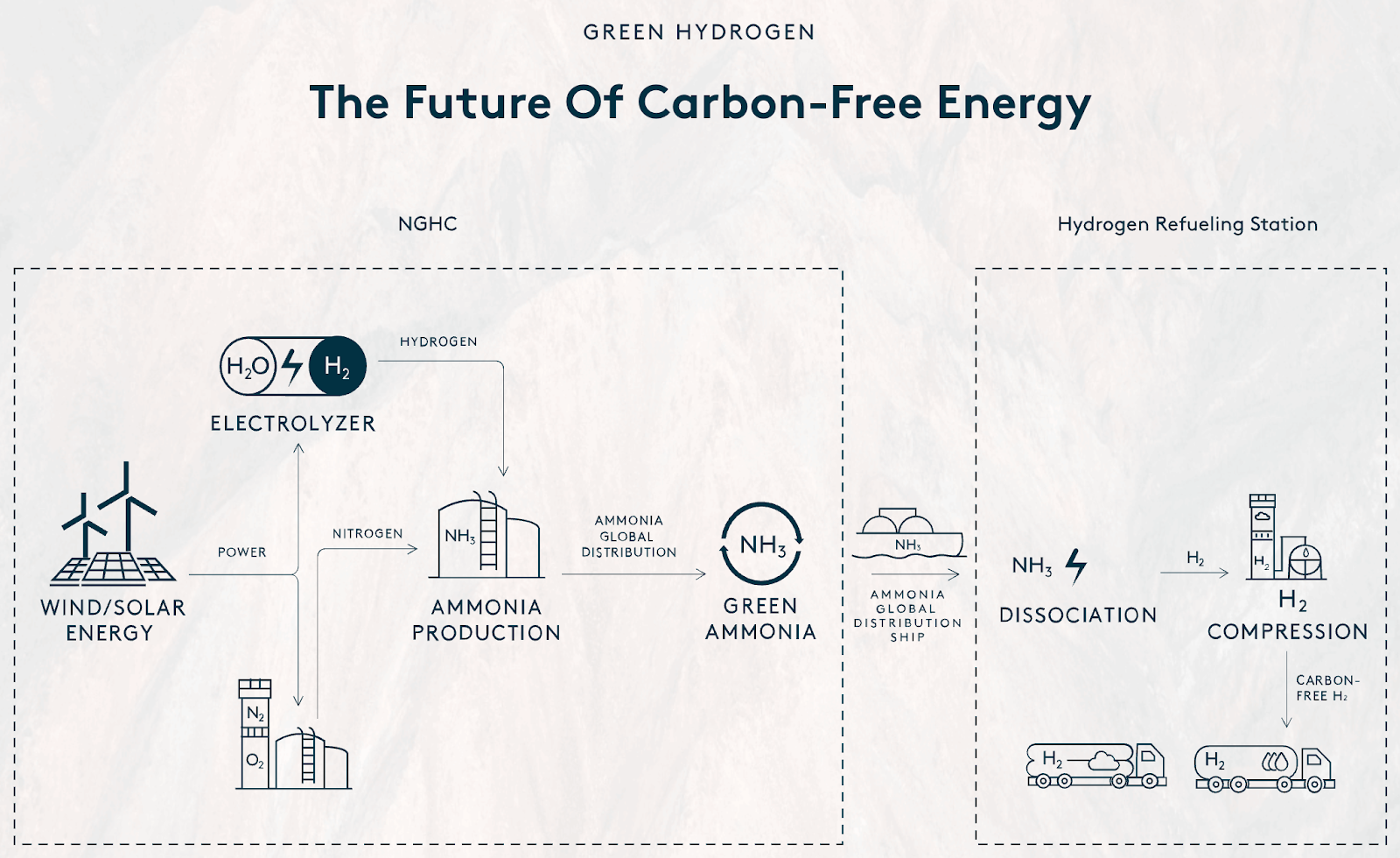

Green hydrogen originates from renewable energy sources like wind, solar or hydro through a process known as water electrolysis, where an electrolyser splits water molecules(H2O) into oxygen gas(O2) and hydrogen gas(H2). This process generates between 0-2.5kg CO2 per kg H211, depending on the source of electricity and efficiency of the electrolysis process, making it the cleanest form of hydrogen we have nowadays. Currently, the costs of green hydrogen are high ($3-$8 per kilogram H2)12, which can explain why it accounts for less than 0.1% of the world’s hydrogen production13. To change that, green hydrogen production facilities need to be developed. In Saudi Arabia, the NEOM project aims to build the world’s largest green hydrogen plant. Only by expanding these structures can the production of green hydrogen become accessible on a global scale.

Yellow hydrogen is also developed using water electrolysis and uses electricity from the general power grid, which is typically a mix of fossil fuels, renewables, and nuclear. As power grids modernise, yellow hydrogen could become the cheapest form of renewable hydrogen in the medium term. Sweden is a great example to follow: approximately 99% of its energy mix is based on clean sources as of 2024.

Purple, pink, and red hydrogen can also be seen as clean energy sources, as they do not emit CO2 during their production. Like green hydrogen, they are products of water electrolysis but powered by nuclear power and heat instead of renewable energy sources. This means that they are zero-carbon emitters if the nuclear source is emissions-free. These hydrogen colours are currently easier to access than green hydrogen, as the production facilities (nuclear plants) are more frequent. However, the price of production can vary significantly from one region to another depending on the political and public acceptance of nuclear plants.

NEOM's Green Hydrogen Production Explained

Potentially Clean Hydrogen Colours in Early Development Stages

Orange Hydrogen targets the production of hydrogen out of plastic waste through pyrolysis, microwave catalysis and photo-reforming. These technical and chemical processes decompose plastic waste in the absence of oxygen using microwave energy and light-activated catalysts. The target is to extract hydrogen from plastic material to turn waste into a valuable energy source. This complex technology still requires fine-tuning and isn’t mature at industrial scale yet. Plastic varies a lot in its composition (polyethylene vs. PVC) making it difficult to extract enough hydrogen. Catalysts are an essential part to the production process but are currently very expensive, prone to errors and not optimised for large-scale production.

Turquoise Hydrogen is hydrogen produced from natural gas following a methane pyrolysis. Natural gas is decomposed into hydrogen and solid carbon at high temperatures. Because the carbon is solid, it isn’t released in the atmosphere but needs to be stored, which can cause additional logistical strains. Maintaining the high temperatures required for the production process is challenging and currently energy-intensive, as well as expensive. Because this hydrogen still requires methane in its production phase, the supply chain leaks can undermine climate benefits. Turquoise hydrogen might need some time before proving itself as a clean solution, but it could well become an alternative.

An insight into the production of turquoise hydrogen:

What to Remember

An energy’s sustainable potential vastly depends on the production process that leads to its existence. Electric Vehicles are undeniably a way to reduce our greenhouse gas emissions, as they directly release far less carbon than cars running on natural gases. However, in order to have a definitive and positive impact on the environment, solutions to reduce our carbon footprint in the production process need further development. If the source of electric power or the batteries remain fossil fuels or other carbon-emitting materials in the long term, we are only hiding and delaying our problems, not finding solutions.

This same principle applies for the further development of hydrogen technologies. In 2023, the International Energy Agency (IEA) estimated that only 1% (!) of the global hydrogen production could be considered as clean. By 2030, projections from McKinsey claim that this number could rise to 30%. An important expansion of clean hydrogen-producing technologies will be vitally important if green hydrogen is to become a globally affordable option.

Current implementations of green hydrogen are already showing promises which could motivate potential stakeholders to further invest in this field. Stay tuned to learn more about these adoptions in our next article on hydrogen!

References:

http://thoughtco.com/elemental-composition-of-human-body-603896

https://www.sciencing.com/what-is-the-mass-percent-of-hydrogen-in-water-13710464

https://www.thoughtco.com/elemental-composition-of-human-body-603896

https://css.umich.edu/publications/factsheets/energy/hydrogen-factsheet

https://montel.energy/resources/blog/blue-hydrogen-vs-green-hydrogen

https://www.sciencedirect.com/science/article/pii/S0360319924014150

https://www.pwc.com/gx/en/industries/energy-utilities-resources/green-hydrogen-cost.html

Written by Léon Pieyre on June 23, 2025