The Solutions Explorer lets you create alerts that match your needs. You can create several alerts and you will receive a notification each time a new Solar Impulse Efficient Solutions is labelled and matches your filters.

Your Search Alerts will show up here.

Sign in to create alerts for your filters and search terms.

Sign inDon't have an account?

Sign upAccess exclusive opportunities for Investor Members Only

The Investment Hub is a platform by the Solar Impulse Foundation that connects innovators with investors to fund scalable and sustainable solutions. Through tailored matchmaking, e-pitches, and a collaborative digital environment, it helps drive impactful innovation forward.

Sign in to explore a world of dynamic and high-potential investment opportunities.

Sign inDon't have an account?

Sign upMarch 20, 2024

Michelin

Clermont Ferrand

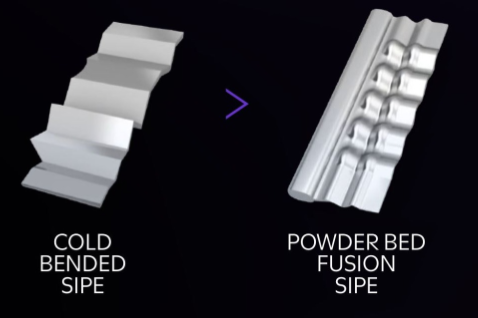

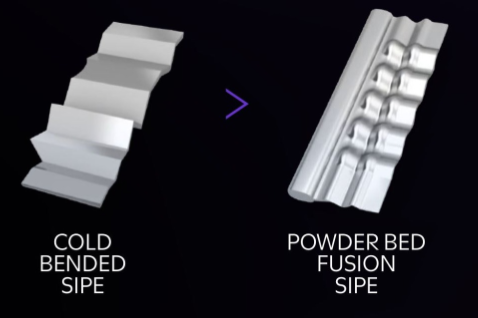

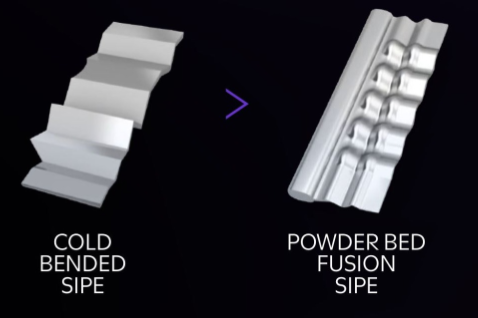

Michelin has been utilizing laser Powder Bed Fusion since the early 2000’s to manufacture tire sipes used within their tire molds. Sipes for tires are designed to improve road holding on wet or wintery roads, while still allowing the rubber to remain rigid, and maintain these levels of rigidity, when the tire is new or worn. By completely transforming the process used to produce parts, additive changed manufacturing at Michelin. There is no longer any need to go through several preliminary steps, nor assemble different components to obtain the desired part.

- Achieved a 60% reduction in global environmental impact compared to the previous aluminum casting solution.

- Cut development time from 9 weeks to just 2 weeks, optimizing resource allocation and project timelines.

The Formup 350 by Addup is an additive manufacturing production machine using the Laser-Powder bed Fusion (L-PBF) technology. A powder bed is locally melted by 4 lasers, drawing on the surface the slice of a part. This routine is repeated consecutively until the height of the part is reached. Our 3D metal printer offers three recoating systems (Brush, roller, silicon blade) allowing unique flexibility to customers and maximizing the reach of the metal 3D technology. FormUp 350 machines are safe, efficient, and scalable, integrating more than ten years of experience built by AddUp and Michelin in PBF technology, with safety at the heart of our concerns.

Share

The information set out above, is solely for the purposes of information and the Solar Impulse Foundation does not provide any guarantee as to its authenticity, completeness or accuracy. This information does not constitute investment advice or a recommendation to buy into, transact or to enter into any agreement with any of the parties or persons mentioned above. Potential investors or interested parties are solely responsible for their investment or business decisions and for performing any due diligence required by the circumstances. The innovator has asserted ownership of the intellectual property rights for images, videos, and content showcased above, affirming full and unrestricted usage rights, and has provided explicit permission for the Solar Impulse Foundation to publish such information designated as "public" in the application form.