The Solutions Explorer lets you create alerts that match your needs. You can create several alerts and you will receive a notification each time a new Solar Impulse Efficient Solutions is labelled and matches your filters.

Your Search Alerts will show up here.

Sign in to create alerts for your filters and search terms.

Sign inDon't have an account?

Sign upMarch 4, 2020

RISE Research Institutes of Sweden

Lulea

The Research Institute of Sweden (RISE) Energy Technology Center issued a tender for a “plasma burner” for R&D experiments on implementation of plasma technology as a heat source for iron ore induration, to lower the GHG impact for steel production. PyroGenesis (PYR) won a competitive bidding process to supply a 600 kW (net) air/nitrogen plasma torch system. The plasma torch was designed to operate with both air and nitrogen between 200 - 600 kW net, inside the pilot steel induration furnace. PYR supervised the installation, commissioning and start-up of the plasma system, achieving 100 hours of operation time and demonstrating comparable furnace heating to the incumbent gas burner. PYR validated their estimated torch electrode erosion rates to project electrode lifetime of several hundred hours. This successful pilot project provided valuable data on torch operation performance and gas emissions to evaluate the replacement of fuel burners with plasma torches.

RISE’s successful trial of the APT-HP reduced energy demand from 1 MW with heavy fuel oil to 900 kW. A study from Chalmers University indicates that, based on these preliminary results, RISE can replace 15.06 MW heavy fuel oil with 14.4 MW using plasma. Estimating a 1 MW: 1 MW full-scale replacement, GHG emissions are slashed by 99.8%. For a plant implementing 80 MW of plasma torch power, annual emissions decrease to about 185 000 tCO2eq, with payback period of 2-3 years and 40% opex reduction.

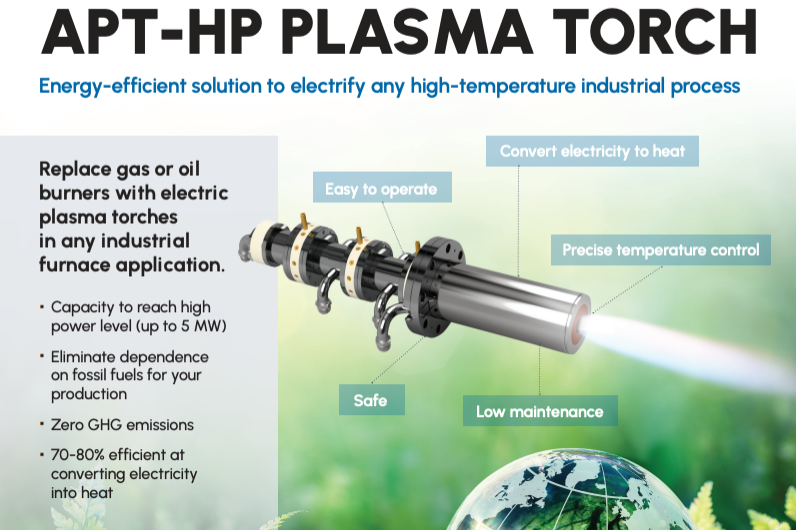

A quarter of global GHG emissions come from the energy-intensive industry sector, necessitating mitigation options beyond energy efficiency to achieve major reductions. PyroGenesis’ APT-HP plasma torch is a compact heater which produces thermal energy from low-carbon electricity for industrial applications, offering an environmentally friendly alternative to fossil fuel burners. The high-power APT-HP (up to 2 MW) provides a plasma plume exceeding 5,000 °C, enabling transformation of raw materials and/or industrial waste into valuable products. The APT-HP offers a lightweight, vortex-stabilized, compact configuration which can be retrofitted into existing installations such as iron ore furnaces and cement kilns, featuring long electrode life, low maintenance, automated operation, and a high level of safety and reliability. Compared to conventional fossil fuel burners, plasma torches using hydropower potentially reduce operating costs by up to 30% and GHG emissions by 98%.

Share

The information set out above, is solely for the purposes of information and the Solar Impulse Foundation does not provide any guarantee as to its authenticity, completeness or accuracy. This information does not constitute investment advice or a recommendation to buy into, transact or to enter into any agreement with any of the parties or persons mentioned above. Potential investors or interested parties are solely responsible for their investment or business decisions and for performing any due diligence required by the circumstances. The innovator has asserted ownership of the intellectual property rights for images, videos, and content showcased above, affirming full and unrestricted usage rights, and has provided explicit permission for the Solar Impulse Foundation to publish such information designated as "public" in the application form.