The Solutions Explorer lets you create alerts that match your needs. You can create several alerts and you will receive a notification each time a new Solar Impulse Efficient Solutions is labelled and matches your filters.

Your Search Alerts will show up here.

Sign in to create alerts for your filters and search terms.

Sign inDon't have an account?

Sign upAccess exclusive opportunities for Investor Members Only

The Investment Hub is a platform by the Solar Impulse Foundation that connects innovators with investors to fund scalable and sustainable solutions. Through tailored matchmaking, e-pitches, and a collaborative digital environment, it helps drive impactful innovation forward.

Sign in to explore a world of dynamic and high-potential investment opportunities.

Sign inDon't have an account?

Sign upAugust 1, 2022

Athenian Brewery S.A.

Stefanovikeio

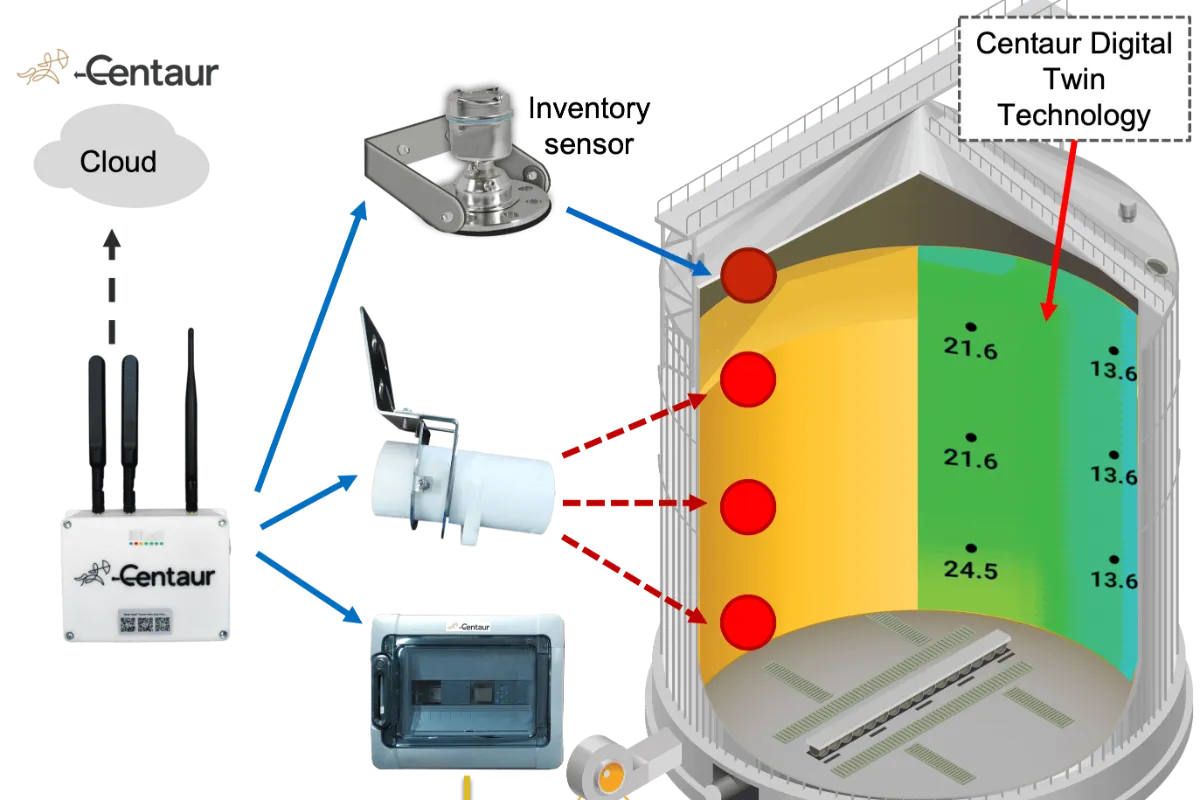

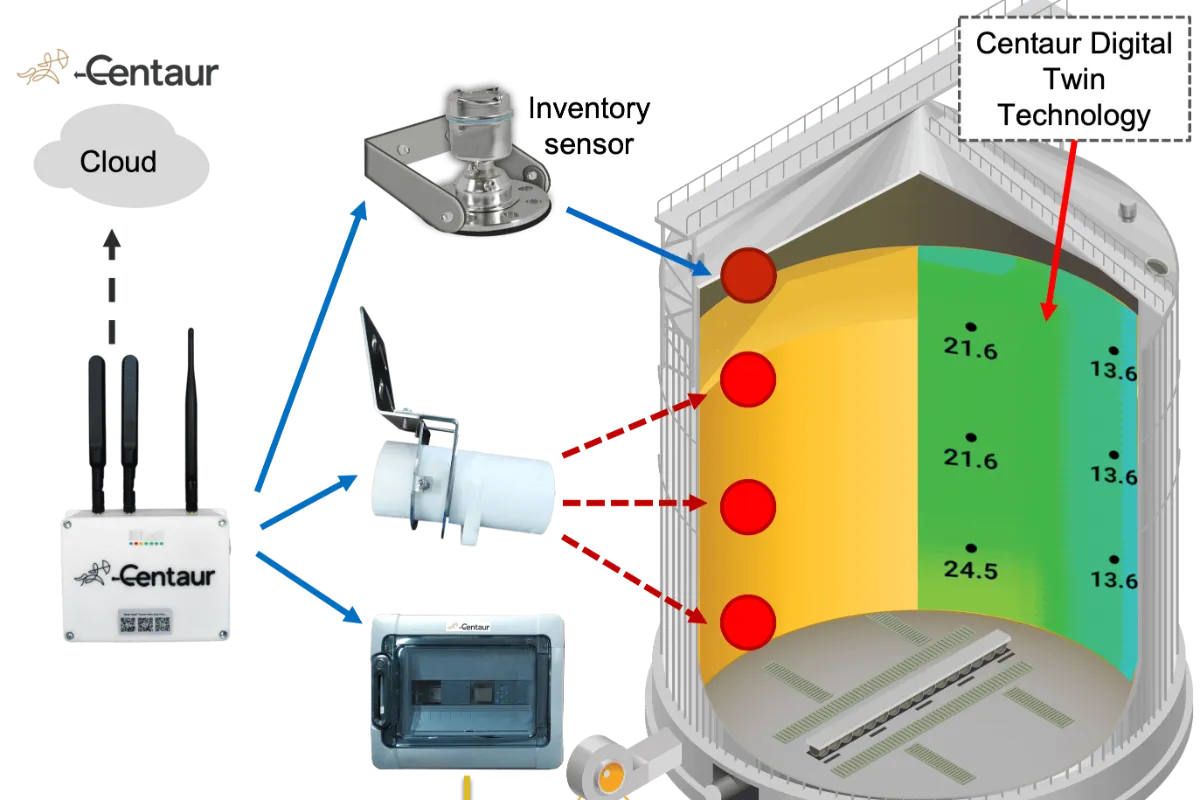

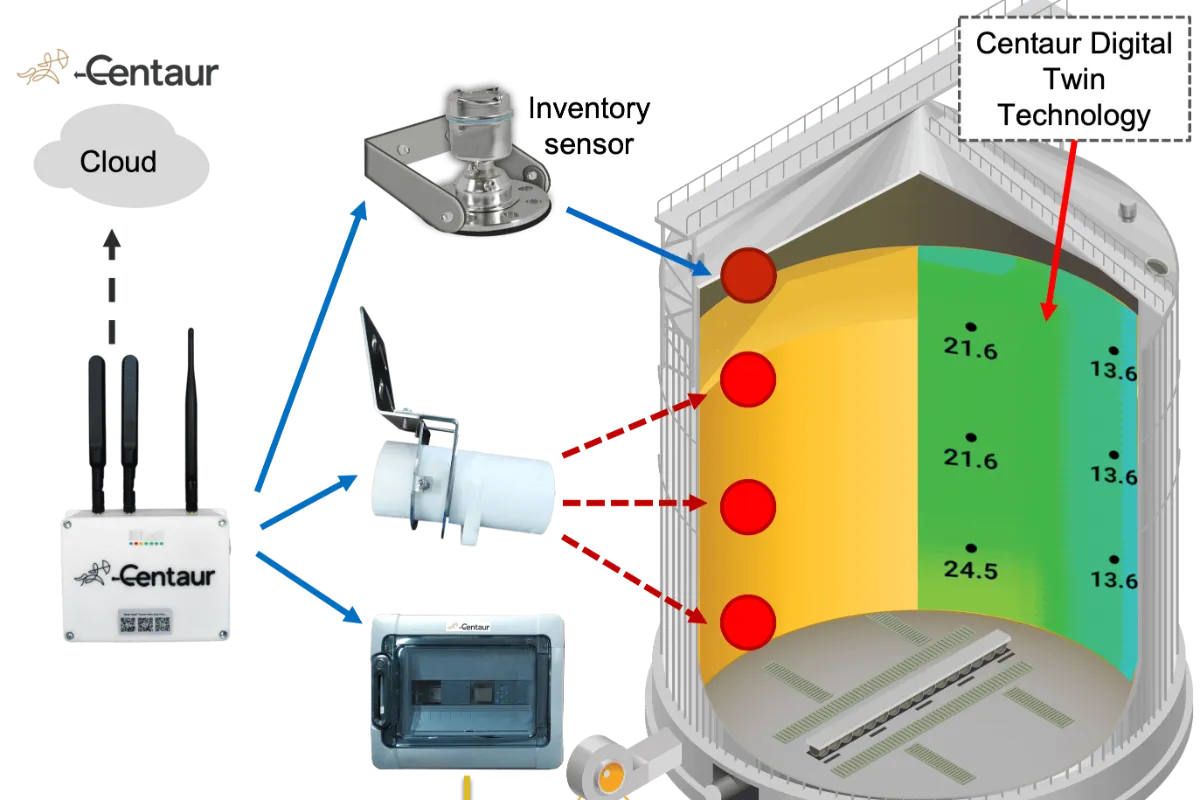

To address climate-driven grain crop degradation, energy waste, and fumigation overuse, Athenian Brewery partnered with Centaur to digitize its malting barley storage. Centaur’s Internet-of-Crops® platform deployed real-time sensor networks, digital twins, and AI-powered analytics to maintain barley germination to 98%, cut pest control chemicals through precision fumigation, and optimize aeration and cooling energy. The solution delivered sustainability gains, quality traceability, and compliance – enabling the Heineken-affiliated brewer to meet top standards while reducing waste and emissions. A proven model for post-harvest digital transformation in food and beverage supply chains.

Centaur preserved malting-grade quality in barley stored over 12 months, preventing 30–50% value loss from deterioration—typically downgraded to animal feed. This protected €80–120/ton in grain value. Precision aeration and fumigation cut energy and chemical use by up to 30%, saving ~50 tons CO₂eq annually per silo (about 10 silos comprised the program). Combined, these delivered payback in under 12 months and significant sustainability gains for the Heineken-affiliated brewery.

Centaur builds a software and sensor-based platform to transform today's grain & cereal bulk supply chain into a trusted, end-to-end, post-harvest quality chain. With its monitoring solution, Centaur offers visibility, quality control, traceability and sustainability along all stages of the supply chain. This is achieved by automatically creating a digital simulation (a "digital twin") of the conditions both inside and outside the grain storage. To achieve this, the Internet-of-Crops platform pulls in all available digital information such as weather and climate data on outside conditions, plus internal conditions identified by sensors (e.g. gas profiles, temperature, moisture levels) and inputs all of this into a state-of-the-art digital model of how grain performs when subject to any and all of these conditions. The result is a state of the art prediction tool of likely problems, allowing remedial action in advance.

Share

The information set out above, is solely for the purposes of information and the Solar Impulse Foundation does not provide any guarantee as to its authenticity, completeness or accuracy. This information does not constitute investment advice or a recommendation to buy into, transact or to enter into any agreement with any of the parties or persons mentioned above. Potential investors or interested parties are solely responsible for their investment or business decisions and for performing any due diligence required by the circumstances. The innovator has asserted ownership of the intellectual property rights for images, videos, and content showcased above, affirming full and unrestricted usage rights, and has provided explicit permission for the Solar Impulse Foundation to publish such information designated as "public" in the application form.