The Solutions Explorer lets you create alerts that match your needs. You can create several alerts and you will receive a notification each time a new Solar Impulse Efficient Solutions is labelled and matches your filters.

Your Search Alerts will show up here.

Sign in to create alerts for your filters and search terms.

Sign inDon't have an account?

Sign upAccess exclusive opportunities for Investor Members Only

The Investment Hub is a platform by the Solar Impulse Foundation that connects innovators with investors to fund scalable and sustainable solutions. Through tailored matchmaking, e-pitches, and a collaborative digital environment, it helps drive impactful innovation forward.

Sign in to explore a world of dynamic and high-potential investment opportunities.

Sign inDon't have an account?

Sign upSeptember 9, 2024

Seppi Gaz

Issenheim

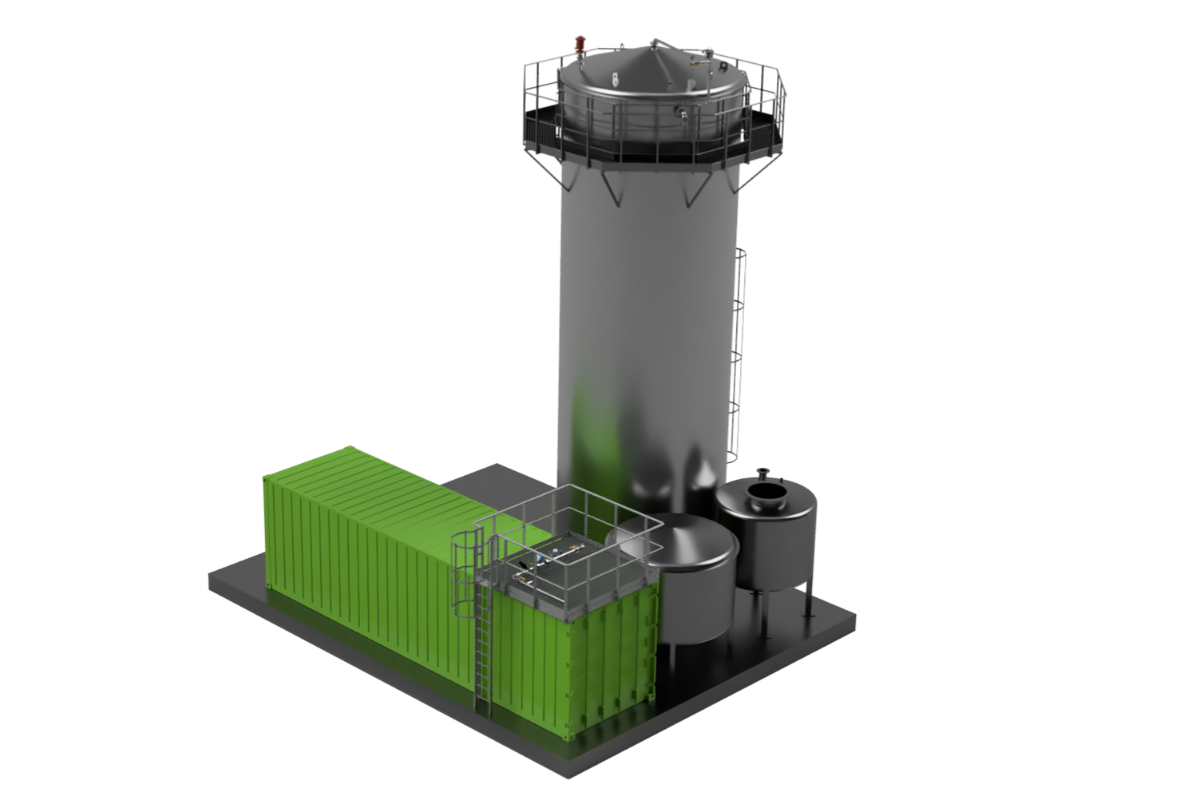

In 2023, SEPPI GAZ SAS launched an anaerobic digestion facility in Issenheim (68 500) to valorize livestock effluents and agricultural by-products, including those from SOJINAL. The increase in volumes requires an innovative and high-performance solution without impacting the agricultural digester. SEPPI GAZ turned to BioRenGaz for a tailored anaerobic digestion unit, structured as follows: 1. Studies: design and engineering. 2. Implementation: manufacturing, installation, commissioning. The innovative bioreactor processes agri-food effluents, including: - Alpro whitewater - Unpacked plant-based milks The installation includes pre-storage (5 m³), a bioreactor (80 m³), a management tank (5 m³), and a technical container. This project optimizes agricultural anaerobic digestion and renewable energy production.

From an environmental perspective, the production of 940 MWh-PCS/year of biomethane saves 171 tCO₂eq/year by replacing fossil gas. Our technology also produces digestate, an alternative to chemical fertilizers (60% of the carbon footprint), the impact of which still needs to be assessed based on its nutrient content (N, P, K). Economically, the investment of €399,012 shows an IRR of 15.2%, a payback period of 5.8 years, and operating expenses of €6,025 per month.

BioRenGaz has developed a patented anaerobic digestion technology that delivers performance four times higher than conventional systems. Thanks to its vertical design, our solution optimizes the footprint of digesters, reducing the required surface area by up to tenfold. It also lowers operational costs by 75% (upflow system, no agitation) while producing 10% more biogas. BioRenGaz has patented the use of wood, sourced from green waste composting platforms, as a growth support to replace expensive plastic carriers. This material provides an eco-friendly habitat for bacteria and enhances their performance. The technology valorizes liquid substrates such as food waste slurries, wastewater treatment plant (WWTP) sludge, liquid waste from the agri-food industry, whitewater, and livestock manure.

Share

The information set out above, is solely for the purposes of information and the Solar Impulse Foundation does not provide any guarantee as to its authenticity, completeness or accuracy. This information does not constitute investment advice or a recommendation to buy into, transact or to enter into any agreement with any of the parties or persons mentioned above. Potential investors or interested parties are solely responsible for their investment or business decisions and for performing any due diligence required by the circumstances. The innovator has asserted ownership of the intellectual property rights for images, videos, and content showcased above, affirming full and unrestricted usage rights, and has provided explicit permission for the Solar Impulse Foundation to publish such information designated as "public" in the application form.