The Solutions Explorer lets you create alerts that match your needs. You can create several alerts and you will receive a notification each time a new Solar Impulse Efficient Solutions is labelled and matches your filters.

Your Search Alerts will show up here.

Sign in to create alerts for your filters and search terms.

Sign inDon't have an account?

Sign upAccess exclusive opportunities for Investor Members Only

The Investment Hub is a platform by the Solar Impulse Foundation that connects innovators with investors to fund scalable and sustainable solutions. Through tailored matchmaking, e-pitches, and a collaborative digital environment, it helps drive impactful innovation forward.

Sign in to explore a world of dynamic and high-potential investment opportunities.

Sign inDon't have an account?

Sign upApril 20, 2025

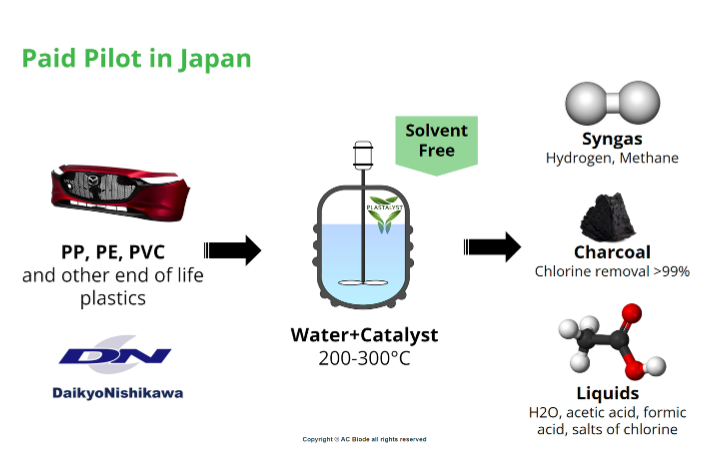

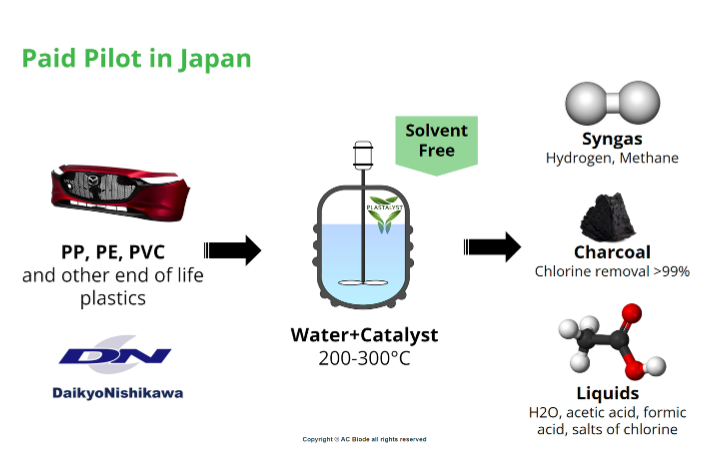

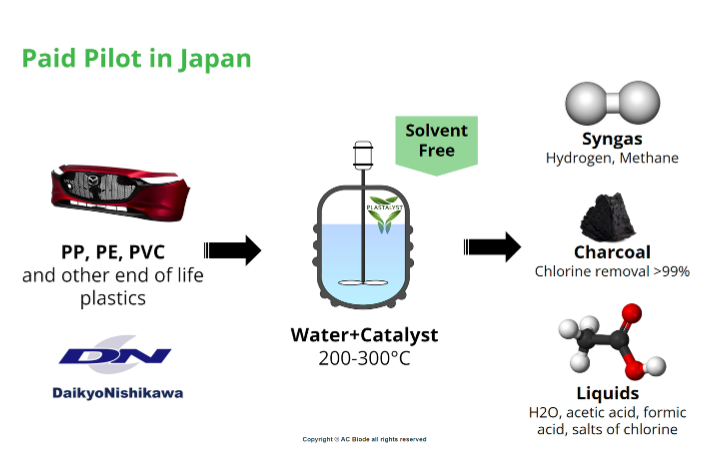

Daikyo Nishikawa

Hiroshima

Plastalyst, developed by AC Biode, addresses the pressing challenge of plastic waste, of which only 9% has been recycled over the past 65 years due to inefficient, costly recycling methods. With EU regulations now requiring 85% of end-of-life vehicle materials to be reused or recycled—despite current materials being suitable only for incineration or landfilling—Plastalyst offers a groundbreaking solution. Using a precious-metal-free catalyst operable below 200°C, the process converts hard-to-recycle plastics into valuable chemicals like monomers, hydrogen, carbon monoxide, and methanol, without producing CO₂ and using only water as a solvent. Following pilot testing with Japanese automotive parts manufacturer Daikyo Nishikawa, AC Biode is now constructing a first-of-its-kind demonstration plant, supported by the Hiroshima Open Accelerator, to advance a circular, zero-waste economy through sustainable chemical recycling.

The impact of a circular plastic supply chain is hard to imagine. Oil and gas companies will be able to make all products cheaper from waste than from crude oil. This will result in a 90+% lower carbon footprint for the new plastics produced.

It is creating a strong secondary economy to collect plastic, elevating millions of people operating in the informal sector from poverty. The environmental impact of less waste in the environment impacts particularly low-income communities.

According to the United Nations (2018), only around 9% of the 6.3 billion tons of plastic waste produced over the last 65 years have been recycled. The problem is that our mechanical recycling cannot process mixed plastic. Pyrolysis is deemed the answer. However, high operating temperatures lead to preventively high costs. Plastalyst is the answer. Through novel catalysts, it can recycle plastic at 90% fewer energy costs. This means that businesses can finally recycle more plastic at low costs.

Share

The information set out above, is solely for the purposes of information and the Solar Impulse Foundation does not provide any guarantee as to its authenticity, completeness or accuracy. This information does not constitute investment advice or a recommendation to buy into, transact or to enter into any agreement with any of the parties or persons mentioned above. Potential investors or interested parties are solely responsible for their investment or business decisions and for performing any due diligence required by the circumstances. The innovator has asserted ownership of the intellectual property rights for images, videos, and content showcased above, affirming full and unrestricted usage rights, and has provided explicit permission for the Solar Impulse Foundation to publish such information designated as "public" in the application form.