Solutions to fight Climate Change

1000+ profitable solutions to protect the environment

To address environmental challenges without compromising economic growth, Bertrand Piccard and the Solar Impulse Foundation have identified 1000+ clean and profitable solutions, and are now committed to going even further. By offering political and economic decision-makers a Guide to Solutions that can be implemented on a large scale, the Foundation will help them establish a roadmap for the adoption of much more ambitious energy and environmental programs and thus achieve their carbon neutrality objectives.

Solutions exist that are logical more than just ecological, that can create jobs and generate profit while also reducing polluting emissions and preserving natural resources.

Bertrand Piccard

Climate Impulse

Flying non-stop around the world in a green hydrogen-powered airplane

Bertrand Piccard unveils Climate Impulse, a new flagship for climate action. After achieving the first circumnavigations of the globe in a balloon and more recently in a solar aircraft, Swiss explorer Bertrand Piccard unveils his new emission-free project: a green hydrogen powered airplane to fly non-stop around the Earth, demonstrating how concrete solutions can help build a cleaner and more efficient world.

Discover Climate Impulse

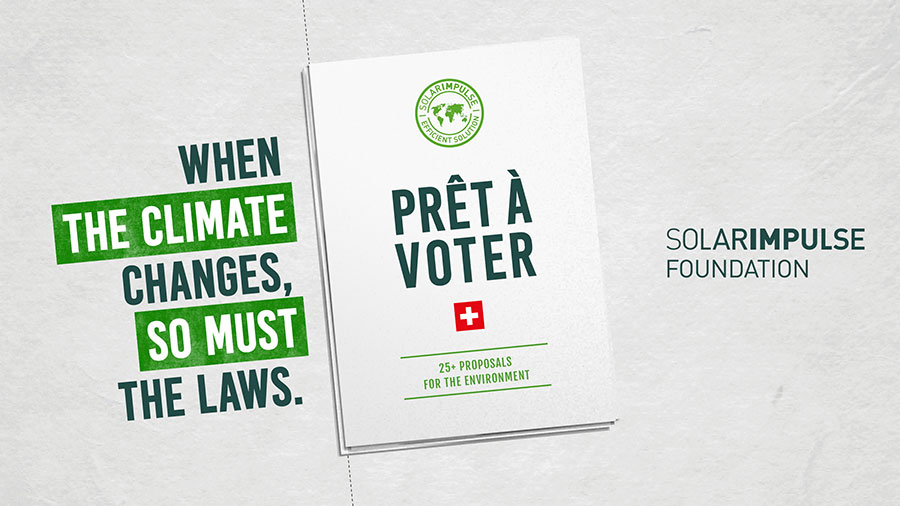

EU Manifesto

Europe 3.0 : Modernise to Thrive !

The EU Manifesto proposes a project for the EU that can unify all political tendencies and visions. It is based on the conviction that the implementation of the Green Deal can be the opportunity to set Europe on a new path, entailing competitiveness, human welfare and environmental sustainability.

Read the manifestoSolutions Explorer

The search-engine for climate action

This dynamic, free-access database showcases 1,000+ clean and profitable Solutions from all over the world which have been assessed by independent experts for their environmental and economic performance.

Solution Explorer allows business, public authorities or individuals to work towards their climate objective. Its user-friendly filtering tool enables Solutions to be selected based on sectors, clients, applications, environmental benefits and technologies.

Label

A label focused on both environment and profitability

An award for clean and profitable solutions. Assessed by independent experts, the Solar Impulse Efficient Solution label, serves as a credible marker of quality to decision-makers in business and governments.This will pull new technologies and products to the market and fast track their implementation.

Learn MoreLatest news

Solutions

The Efficient Solutions portfolio

A « pool » of solutions, ready to be promoted among decision-makers. By bringing to decision-makers 1000+ clean and profitable solutions, Bertrand Piccard wants to demonstrate to decision-makers the financial profitability of clean technologies and therefore, push governments to adopt more ambitious energy policies and environmental targets.

Solutions1578

under

Assessment80

1000 WAS OUR FIRST MILESTONE. BUT WE’LL KEEP LABELLING SOLUTIONS BEYOND 1000.

SO KEEP INNOVATING!

Latest labelled solutions

Bertrand Piccard

A voice to encourage the implementation of solutions

A pioneering vision, considering ecology through the lens of profitability. As an influential voice on progress and sustainability, Bertrand Piccard is now working to develop collaborations with governments, institutions and large companies to give them practical tools to reconcile ecology and economy and prove that solving climate change - rather than an expensive problem - is a fantastic market opportunity.

Learn MoreDiscover the New Climate Narrative

World Alliance

An alliance to federate

A global strike force to fast-track solutions. Strong believer in the power of synergies and in the need to bring together clean technology players, Bertrand Piccard has launched the World Alliance for Efficient Solutions. This Alliance comprises 4780 innovators, investors, adopters, promoters, and, most importantly, a "pool" of efficient solutions assessed by a community of 301 experts. Our mission is to promote these efficient solutions among decision-makers, the media, and the public, ultimately boosting their adoption.

Learn MoreTopics we focus on

Historic Flight

A historic first

A first in energy to showcase the potential of clean technologies. When Bertrand Piccard and André Borschberg succeeded in flying 43,000 km around the world in a solar-powered airplane without using a drop of fuel, it was more than a historic first, it was a first in energy highlighting the potential of clean technologies that can do more than we ever thought possible, reducing our energy consumption, protect natural resources and improve the quality of life on Earth.

Learn More